Design

Makia Produces Nordic contemporary clothing to stand the test of time, equally in quality and over trends, to become a part of our everyday lives.

We thrive to make our designs as usable and functional as possible, no-nonsense clothing that you won’t want to throw away. Our goal is to minimise the problem of getting dressed appropriately, so you’ll have time to worry about the bigger picture, whether it means waking up to a hectic routine with kids, an overwhelming day at work, or just plain harsh weather.

Nordic design has its foundation on functional thinking, as the climate dictates much of how we need to get dressed. The materials and styles we use need to adapt to nature’s elements as well as the urban environment.

Longevity is the key to a more sustainable consumption. By simply wearing our clothes twice as long as we do now, we could potentially reduce the greenhouse gas emissions of the textile industry by 44%, according to the Ellen McArthur Foundation report. This is why we encourage our customers to take a moment before each purchase and ask themselves: Do I really need this product? We welcome both answers.

Longevity is about physical durability, a well-designed good quality product that can also be repaired. Longevity is also about emotional durability, that derives from timeless and functional design that you want to wear over and over again.

Upcoming EU regulation and textile strategy 2030 aims for clothing, accessories and footwear that are long-lived, recyclable, and made of recycled fibers while being free of hazardous substances and compliant with social rights. We think that Makia’s dna is compliant with the EU’s vision but a lot of work needs to be done, since there is no finish line in this race.

Makia is part of Manna&Co group that includes Finlayson, Vallila, Reino&Aino and Lexington Company brands. Sustainability is the corner stones of Manna’s daily business. Sustainability work’s focus areas are products and production, the environment and climate as well as people.

Design

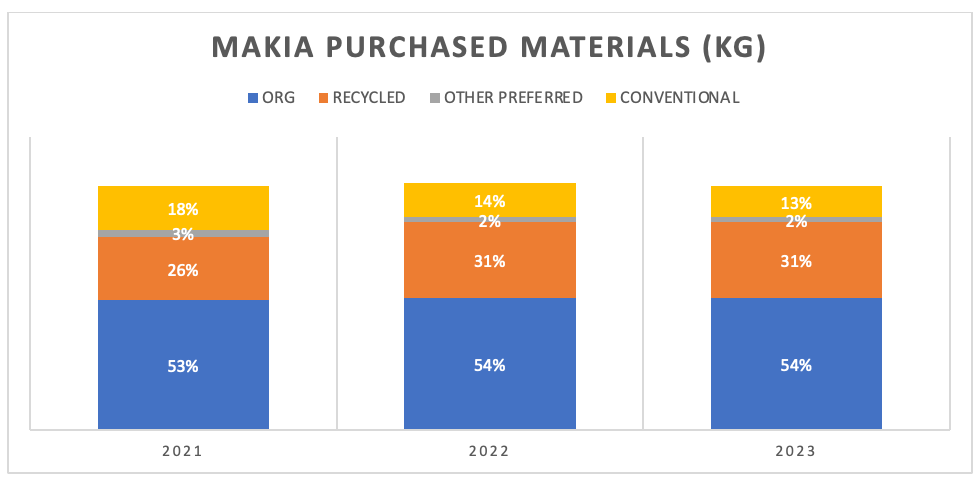

Currently 87% of our manufacturing comprises from preferred materials.

Makia is counting the following fibres as preferred materials: organic cotton, recycled cotton, organic wool, recycled polyester, TENCEL™ Lyocell, LENZING™ ECOVERO™ viscose and LENZING™ Modal. Makia has selected these fibres based on the Textile Exchange’s Preferred fiber & materials- report.

Manna group is targeting 90% use of preferred materials by 2032.

Cotton / Organic Cotton / Recycled Cotton

General cotton information

Cotton is one of the most used textile fibres in the world. Cotton’s share from global fibre production was 20% in 2023 (Textile Exchange, Materials Market Report 2024). Although cotton is a natural fibre, it is also one of the most unecological ones. Cotton plant is quite demanding, it requires fruitful ground, warm climate and a lot of water. Large crops are being manufactured with a lot of artificial fertilizers for better growth and dangerous chemicals for reducing pesticides. These chemicals are harmful for the environment, animals as well as humans. A single cotton t-shirt requires 2700 litres of water according to the World Wildlife Fund (WWF). Conventional cotton water is mostly coming from irrigation.

Organic cotton is cultivated without artificial fertilizers and pesticides. It uses only non-GMO seeds, crop rotation and manual picking. It reduces the environmental impact greatly. It is a safer option for the environment as well as people. Although organic cotton requires as much water as the regular cotton, organic cotton is more rain-fed. Fibre qualities are the same as regular cotton but without any harmful chemicals that might cause skin irritation. Lack of chemicals is good for the cotton farmers, soil as well as end-consumers.

As a fibre cotton is soft, breathable and absorbent. It is also strong and can stand up against wear and heat. On the other hand, it wrinkles easily, is prone to shrinking and is slow to dry.

Cotton production

World biggest cotton producers in 2023/2024 (ICAC, World Cotton Statistics, 2024)

1. China 2. India 3. Brazil 4. USA 5. Pakistan

World biggest organic cotton producers (2020/2021, Textile Exchange, Organic Cotton Market Report, 2022)

1. India 2. Turkey 3. China 4. Kyrgyzstan 5. Tanzania

Makia is using cotton or cotton mixed fabrics in many product categories, mainly in jersey products as well as in men’s woven shirts and trousers. Cotton has a soft feel, it is quite durable and easy to care.

Makia cotton / organic cotton usage / recycled cotton* usage:

(includes cotton/elastane but excludes other mixed qualities // *includes recycled cotton/recycled polyester, where cotton exceeds 50%)

2018: 51,5% / 4,4% / 7,5*%

2019: 54,9% / 3,7 % / 5,9*%

2020: 17,6% / 47,0% / 7,2*%

2021: 5,6% / 53,4% / 2,2*%

2022: 3,9% / 52,5% / 1,6*%

2023: 6,1% / 53,5% / 1,2*%

Makia is using mostly certified organic cotton that is farmed and processed entirely in Turkey.

Wool / Merino Wool

General wool info

In 2023 0,9% of global fibre production was wool (Textile Exchange, Materials Market Report 2024). Wool is a natural fibre that comes from sheep / Merino sheep. Sheeps are grown in large herds that require large land areas where sheep cause erosion and lessens the natural diversity. Sheep also produces methane gas which is a strong greenhouse gas. The shearing is normally done once a year, where the wool is removed from the animal.

Mulesing is the removal of strips of wool-bearing skin around the breech of a sheep to prevent the parasitic infection flystrike. The scar tissue that grows over the wounds does not grow wool and is less likely to attract the flies that cause flystrike. Mulesing is a common practice in Australia, particularly on Merino sheep. Other wool producing countries have banned mulesing or are naturally mulesing free.

Wool has great fibre qualities. Wool is an active fibre that helps you stay warm when the weather is cold and cool when the weather is hot. Wool is absorbent and can hold moisture well, without feeling cold. Merino wool even absorbs the odour molecules from sweat. Wool fibre is naturally elastic and ideal for moving and exercising. Wool has also a protective outer layer that helps prevent stains from being absorbed. The most important care instruction for wool products is airing and lint brushing, if they don’t have stains.

Wool production

World biggest wool producers (Textile Exchange, Materials Market Report 2024):

1. Australia 2. China 3. New Zealand 4. Turkey 5. South Africa

Makia is using Turkish origin certified organic wool. Merino wool that Makia uses is coming from multiple origins. All Merino woolen accessories are made from mulesing free wool mainly from South Africa or New Zealand, but we cannot be sure of the knitted merino wool apparel’s mulesing status. Hence, we don’t claim them to be mulesing-free.

Makia wool / Merino wool usage (excluding mixed fabrics):

2018: 1,4% / - / 11,0%

2019: 0,8% / - / 15,5%

2020: 0,9% / - / 8,5%

2021: 0,4% / - / 7,0%

2022: 0,0% / 1,1% / 3,6%

2023: 0,3% / 0,2% / 2,0%

Leather

Leather is very durable, breathable and it can be easily cared for. Leather products age well and become softer and better fitting when worn.

Makia used leather in shoes and accessories but has now stopped leather production in 2023.

Makia was working with two tanneries, and they were both certified by the Working Leather Group. Leather Working Group is a non-profit organisation responsible for the world’s leading environmental certification for the leather manufacturing industry. The upper leather in Makia shoes was from cow and lining from pig. All linings where the shoe is in contact with your skin are made from chrome-free and vegetable tanned leather.

Makia leather usage:

2018: 5,5%

2019: 3,1%

2020: 2,4%

2021: 3,9%

2022: 5,4%

2023: 2,0%

Other animal fibres

We don’t use any vulnerable, endangered, exotic or wild-caught species, fur or rabbit hair, feather or down, bone, horn, shell, teeth or cashmere silk.

Polyester / Recycled Polyester

General polyester info

Polyester is the most used fibre in the world with a 57% share of the global fibre production (Textile Exchange, Materials Market Report 2024). Polyester is a synthetic fibre derived from oil and is the most used fibre in the textile and apparel industry. Polyester fibre is light, strong and does not absorb water and can be produced in a way that transfers moisture away from skin. Polyester products are also easy to wash, and they dry quickly. Polyester is non-biodegradable. Polyester production has less environmental impact than natural fibres in terms of water and wastewater, but it requires more energy and chemicals, causing also more greenhouse gases.

Recycled polyester is usually made from plastic bottles. Using recycled polyester uses 30-50% less energy and reduces the need for crude oil. Unfortunately, each cycle when plastic is reheated it degrades and cannot be recycled indefinitely.

Makia is using polyester in jackets and bags due to its suitable qualities to these products. We are nowadays mainly using recycled polyester and recycled polyamide.

Recycled polyester is usually made from plastic bottles. Using recycled polyester uses 30-50% less energy and reduces the need for crude oil. Unfortunately, each cycle when plastic is reheated it degrades and cannot be recycled indefinitely.

Makia is using polyester in jackets and bags due to it’s suitable qualities to these products. We are nowadays using only recycled polyester.

Makia polyester / Makia recycled polyester usage:

2018: 4% / 0,1%

2019: 1% / 5%

2020: 1% / 7%

2021: 0,7% / 23,5%

2022: 0,4% / 29,3%

2023: 1,9% / 29,6%

Lyocell

TENCEL™ Lyocell is a registered trademark of Lenzing for lyocell fibre. Fibre is made from dissolving pulp which comes from sustainably grown wood using a unique closed loop system, making it a sustainable selection. Process is similar to viscose but without the use of harmful carbon disulfide.

TENCEL™ Lyocell fibre is from botanic origin and breathable, absorbent, strong and soft to touch. It has better softness and moisture absorption capacities than cotton, making your skin feel cool and comfortable.

Makia Tencel usage:

2018: –

2019: 0,2%

2020: 2,1%

2021: 1,9%

2022: 1,3%

2023: 1,3%

LENZING™ ECOVERO™ viscose

LENZING™ ECOVERO™ viscose is another registered trademark of Lenzing. It is made from certified wood sources using an eco-responsible production process. Process has 50% lower water impact, up to 50% less air impact than generic viscose (confirmed by Higg MSI; cradle to fiber production gate). Fibre is certified by EU Ecolabel.

Makia LENZING™ ECOVERO™ viscose usage:

2021: 1,4%

2022: 0,2%

2023: 1,1%

Chemicals

All our products follow EU’s Reach regulation about chemicals. We also do not use heavy metals, azo dyes, phthalates or PVC, and we only use ecological coatings in our jackets.

Supply chain

We value long-term relationships with our business partners, and we are in constant dialogue with our manufacturing partners.

In 2023 97% of our production volume came from suppliers that we have worked with for 5 years or more. Our products are manufactured in Turkey, China, Finland, Portugal and Bulgaria. EU production summed up 5%.

Turkey is our main source of production, and they supply our jersey goods, shirts and trousers. Most of our jackets and bags are made in China and our footwear and socks come from Portugal. Bulgaria is producing knitwear and knitted accessories. We also produce high quality woollen accessories in Finland.

We have worked together with our main manufacturing partners for years, and we visit the manufacturing sites regularly. Our major manufacturing partners have all signed Makia’s code of conduct that is based on international conventions such as the UN Declaration of Human Rights, the Children’s Rights and Business Principles, Global Compact and International Labour Organization (ILO) Conventions and Recommendations relevant to improve working conditions in the supply chain. All our garments comply with the European Union reach regulations.

For better transparency of our production, all our garments are labelled with the country of origin, which is the place where the final form of the product is given. From the beginning of 2019 we also inform where the main material is made as well as what is the main material fibre origin.

We have worked together with our main manufacturing partners for years, and we visit the manufacturing sites regularly. Our manufacturing partners have all signed Makia’s code of conduct that is based on international conventions such as the UN Declaration of Human Rights, the Children’s Rights and Business Principles, Global Compact and International Labour Organization (ILO) Conventions and Recommendations relevant to improve working conditions in the supply chain. All of our garments comply with the European Union reach regulations.

For better transparency of our production, all of our garments are labelled with the country of origin, which is the place where the final form of the product is given. From the beginning of 2019 we also inform where the main material is made as well as what is the main material fibre origin.

Turkey is our main source of origin. We purchase most of the jersey, knitted apparel and woven items from Turkey.

Textiles and fashion are a major industry for Turkey and in 2020 it was the world’s 7th largest exporter with 27.5 billion USD. Turkey has a modern and versatile textile industry and includes all parts of the supply chain. There are over 50 000 companies with most of them small and support one or two parts of the supply chain. This enables small and flexible production with quick lead times in comparison to the Asian suppliers.

In 2023 Makia produced 57% in Turkey. Makia has three 1st tier partners in Turkey, two factories in Izmir and one in Denizli.

Yototeks Tekstil Urunleri San Ticaret Limited Sirketi – Jersey factory, Izmir

Founded: 2005

Employees: 33 person, 55% women

Products: jersey for men, women and kids (t-shirts, long sleeves, sweatshirts); woven items for women (blouses, skirts, dresses, trousers)

Partnering with Makia: 2011

Yototeks factory is run by two women Gulsen and Zeynep. Gulsen’s Belgian husband was selling textiles to Finnish customers and popped into Makia’s office in 2009. Our collaboration started then and Yototeks has grown to become our largest supplier. Yototeks has production planning, cutting and sample sewing room in-house and they use local partners for production sewing, printing and embroideries. Factory has amfori BSCI audit with ranking B.

Ege Örgü Triko – knit factory, Izmir

Founded: 2002

Employees: n/a

Products: knits and knitted accessories for men, women and kids (knits, beanies, scarves)

Partnering with Makia: 2019

We came upon this knit factory via our Izmir contact Yototeks. Ege Örgü has a good, modern range of flat knitting machinery and they work with high quality yarns from Turkey and Europe. The knitting factory has knitting, washing, cutting, planting and packaging under one roof.

Nakosan Textile – knit factory, Denizli

Founded: 1986

Employees: 250

Products: knits and knitted accessories for men, women and kids (knits, beanies, scarves)

Partnering with Makia: 2022

Makia started working with Nakosan via Finlayson’s Denizli contact. Nakosan is a family run business with a focus on sustainable production. They have several certificates for sustainable materials (GOTS, OCS, Oeko-Tex 100, GRS, CRS) and hold amfori BSCI audit with rank B.

China is the origin for Makia’s jackets, bags and caps.

China was the world’s biggest economy in 2020 and has grown to become the largest textile and fashion producer in the world growing rapidly in the last two decades. China’s exports grew to 266 billion USD* in 2020 and it was by far the largest textile and clothing exporter. China’s massive textile industry includes all production stages from fibres to ready-made garments.

In 2023 Makia produced 36% in China. Makia has two 1st tier factory partners jackets and several European companies for bags and caps that have the production made in China. Makia is mainly purchasing products made from recycled materials from China.

DanYang BoKang Garment Co.,LTD – jacket factory, Nanjing

Founded: 2011

Employees: 20 person, 80% women

Products: woven jackets for men, women and kids

Partnering with Makia: 2014

Makia came across with this jacket factory via their Swedish customer in 2014. Soon after we started the co-operation we visited them in person and the partnership has developed ever since. We have visited local textile fairs with them and are constantly developing our materials and products. The factory has amfori BSCI certification with rank C and does cutting, sewing, finishing and packing in-house.

Anqing Image Garments Co. Ltd – jacket factory, Anqing

Founded: 2010

Employees: 75 person, 72% women

Products: woven jackets for men, women and kids

Partnering with Makia: 2015

Makia contacted Anqing Image Garments via a Finnish sourcing agency, Nikolai Sourcing. This factory has amfori BSCI (rank C) and ISO9001/14001/45001 certifications and has cutting, sewing, finishing and packaging operations.

In Finland Makia purchases knitted accessories, beanies and scarves.

Finland has a long history in the textile sector but like in similar European countries, the production has shrunk from the heights of the 1970-80’s. Today Finland has approximately 650 companies and 1 billion euro turnover in the production sector (60% garments, 40% textiles) with around 4400 jobs.

In 2023 Makia produced 3% in Finland. Makia has one 1st tier factory partner located in Finland and several partners that have production outside Finland.

Nevertex Oy – knitted accessories factory, Yli-Ullava

Founded: 1986

Employees: 22 person, 87% women

Products: knitted accessories

Partnering with Makia: 2015

Nevertex is one of the few companies that have a commercially sized production in Finland. They have specialized in flat-knitted accessories made mainly from woolen yarns. They have a very flexible production and they offer a wide range of tailor-made services, designs and different yarn options for their wholesale customers. Nevertex uses mainly high-quality yarns from European yarn brands and they work only with mulesing-free merino wool.

Napakka Oy – tote bags wholesaler, Helsinki

Founded: 1984

Employees: 21 person

Products: all types of bags

Partnering with Makia: 2010

Napakka is a wholesaler in packing that offers paper and woven bags, gift wraps, ribbons, tapes, boxes etc. All items can be branded according to customers wishes. Makia has worked with Napakka over ten years and purchases tote bags that are mainly made from recycled materials as well as different materials to our retail stores. Products are made in China in a factory that has GRS and amfori BSCI certificates (rank C). In 2023 >1% of Makia’s production volume was purchased from Napakka.

In 2023 Makia produced >1% from Bulgaria. Makia has two 1st tier factory partners in Sofia via a local agent.

Sentex-69 Ltd and Texanna Ltd – knitted apparel and accessories factory, Sofia

Founded: 2001

Employees: 21 person, 81% women

Products: knitted apparel and accessories

Partnering with Makia: 2015

Sentex-69 and Texanna are small, family run businesses focusing on high quality knitted apparel and accessories. They have an ISO 9001 certificate.

In Portugal Makia purchases socks.

Portugal is the 5th largest EU country in textile and clothing production revenue and in 2021 comprised of 18% of both companies and employees in the total manufacturing industry in Portugal according to AICEP Portugal Trade & Invest report. Today Portugal has approximately 12 000 companies and 8 billion euro turnover in the textile. Industry employs over 126 000 thousand people, with 84% of them are working in the Northern Portugal, Braga and Oporto regions.

In 2023 Makia produced >1% in Finland. Makia has one 1st tier factory partner located in Portugal.

AJ Goncalves – sock factory, Braga

Founded: 1966

Employees: n/a

Products: socks and tights

Partnering with Makia: 2015

AJ Goncalves is a family run sock factory in the Northern Portugal, Braga region. Company was founded in 1966 and since then has produced different kinds of socks and tights for men, women and children using all kinds of materials. They have two in-house brands and chain of shops in Portugal and Spain. Makia has been working with AJ Goncalves since 2015.

Trimmings

Makia started to work with Danish A-tex (Trimco Group) in 2019. A-tex is a global supplier of sustainable brand identification products with innovative techniques and global reach. Our aim was to get unified, high quality and sustainable trimmings to all of our products, no matter the origin. A-tex supplies all Makia’s hangtags, woven labels, care labels and polybags and other general trimmings that we use in our products. They are all made from recycled materials either in Turkey or China.

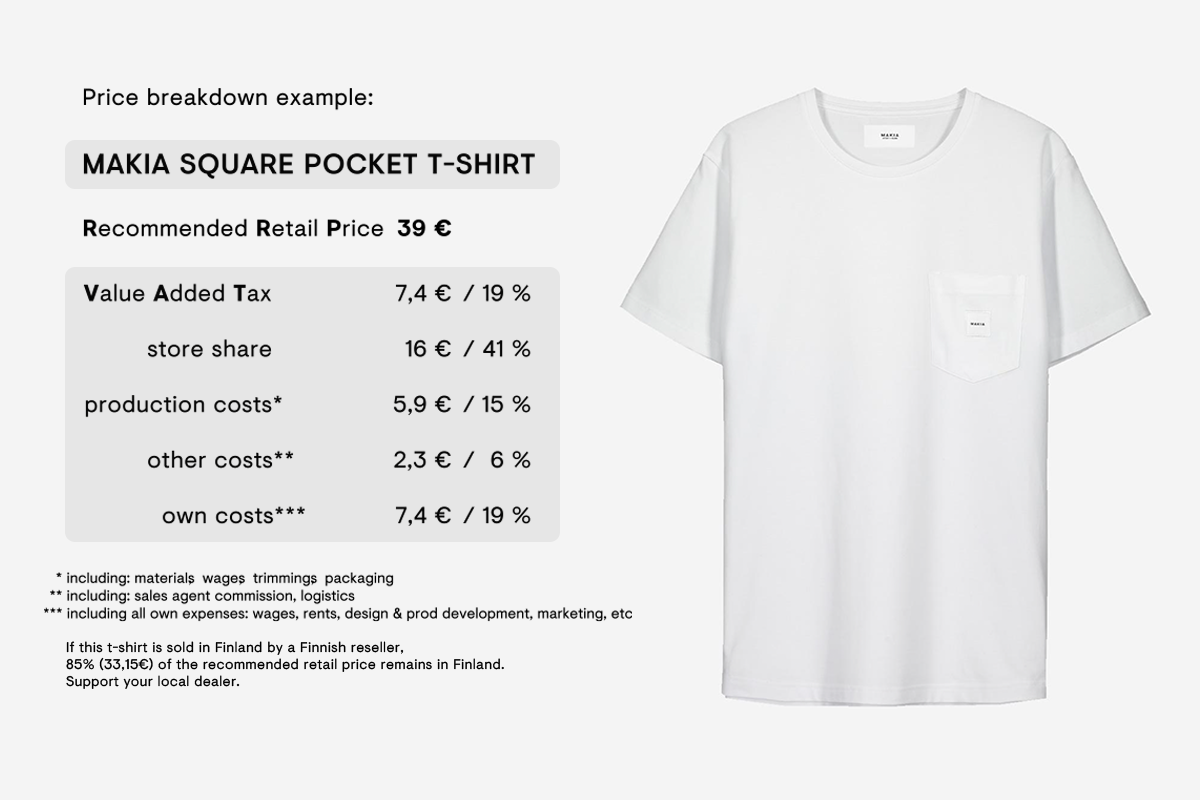

Price breakdown example (wholesale)

By this example we want to demonstrate the value chain that forms the end price of a product.

Packaging & Logistics

We are working towards minimising packaging waste in the supply chain from the suppliers to our warehouse and to end-consumers.

To protect our good quality products during transportation and warehousing, we’ve packed them into polybags. In 2021 we switched to 100% recycled polybags. In 2019 we tested biodegradable corn starch packaging but found out that there was no suitable infrastructure to handle compostable material in the retail sector and the quality of the corn starch material was not up to our standards. In webstore deliveries we are using light weight plastic bags, that are made out of >80% recycled low density polyethylene (LDPE). Bags can also be used in return shipments.

In inbound logistics Makia is focusing on truck shipments from Europe and sea cargo from Asia. We try to avoid air cargo but occasionally we have to use it due to timetable reasons. In outbound deliveries we use truck shipments in our wholesale shipments and in webstore shipments, customers can choose what shipping method they wish. We offset CO2 emissions on all shipments that are made with DHL or UPS. Other forwarding partners are not offering compensating schemes, but they are working towards cleaner transportations with for example electric vehicles in the last mile deliveries.

For a sustainable future

For a sustainable future

Makia has initially selected these three Goals according to the United Nations Sustainable Development Goals.

12 Responsible Consumption and Production: Makia’s concept for producing clothing that stands the test of time, both in terms of quality and trends, supports the UN’s SDG 12 for sustainable consumption and production. We are now focusing on using more sustainable materials in our collections and educating customers about caring for their garments well to ensure longer lifecycles and less environmental impact.

14 Life Below Water: Makia was founded in 2001 in an old Helsinki dockyard neighbourhood called Punavuori. The sea is close to our hearts and it affects our daily lives, so we must take care of it and preserve it for future generations. We support the protection of the Baltic Sea and Finnish inland lakes in close collaboration with Keep the Archipelago Tidy Association and the John Nurminen foundation with donations and educational marketing collaborations.

15 Life On Land: Makia has set a target of using 75% Environmentally Preferred Materials in our production by 2025. In 2020, we are changing most of our conventional cotton to organic cotton. We are also following new inventions in material R&D (pulp, pineapple, etc.) and we work with carbon neutral transportation partners (DHL & UPS). What we can all do now is to start using our clothing for longer in order to greatly lessen their environmental impact. We want to lead by example in setting this trend.

The United Nations Sustainable Development Goals are the blueprint for achieving a more sustainable future for all. They address the global challenges we face, including those related to poverty, inequality, climate, environmental degradation, prosperity, peace and justice. The goals are interconnected, and in order to leave no one behind it’s important that we achieve each of them by 2030.

CO2 emissions

Makia has committed to the Finlayson&Co groups sustainability targets and we've set these targets to mitigate the climate change: carbon neutrality for our own greenhouse gas emissions (Scope 1 and 2 emissions) by 2025 and for the whole value chain (Scope 3 emissions) by 2035. In 2022, approximately 97 percent of our greenhouse gas emissions came from Scope 3 emissions, i.e. the supply chain and materials. Our objective is to reduce these emissions together with our partner network by, for example, increasing the use of environmentally friendly materials. Materials that are better than average for the climate include organic and recycled fibers, hemp and linen. Another major source of emissions is energy, which is why we encourage our partners to utilize renewable energy sources.

Read more from https://mannagroup.fi/en/sustainability/.

Saving the Baltic Sea

We contribute towards the environment by taking part in conservation projects preserving the condition of the Baltic Sea with John Nurminen Foundation and Keep the Archipelago Tidy Association. So far Makia has donated over 63000€ (excl VAT) to Baltic Sea preservation.

For a good cause

Makia is also working with charity organizations Apuna ry, The Finnish Association for Nature Conservation (Suomen Luonnonsuojeluliitto) and Cup Of Therapy.

Last and not least, make sure to follow the instructions on the care labels to make your products last as long as possible.